Furnace installation in Chicago depends heavily on the type of fuel that powers the heating system. Each furnace fuel type—natural gas, propane, electric, or oil—requires specific installation methods, venting systems, and safety measures. Choosing the correct fuel type affects operating efficiency, temperature rise, static pressure balance, and long-term cost of ownership. A properly installed furnace matched to the right fuel source provides quiet operation, reliable heat, and compliance with local building and safety codes. Understanding how each fuel works and what the installation involves helps homeowners plan effectively for Chicago’s demanding winter conditions.

How Fuel Type Influences Furnace Installation

Fuel selection determines nearly every aspect of the installation process, from venting design to combustion air requirements. Natural gas furnace installation is most common in the city due to its wide availability and cost stability. Propane furnace installation serves areas without gas service and relies on outdoor storage tanks and regulators. Electric furnace installation eliminates combustion entirely but requires strong electrical capacity and proper circuit protection. Oil furnace installation remains a niche option but offers robust heating output and durability in older homes. Every type must maintain correct static pressure, temperature rise, and airflow balance to achieve safe, efficient performance.

Efficiency and Performance Across Fuel Types

Furnace efficiency is measured by AFUE, or Annual Fuel Utilization Efficiency, showing how much fuel energy becomes usable heat. Modern high efficiency gas furnace installation achieves between 90% and 98% AFUE using condensing technology and sealed venting. Propane systems reach similar performance when equipped with high efficiency burners and proper vent slopes for condensate return. Electric furnaces operate at nearly 100% AFUE because all electricity converts directly into heat, though total cost depends on energy rates per kilowatt-hour. Oil furnaces range from 80% to 90% AFUE and require annual service to keep combustion clean and consistent.

Technical Factors That Affect Installation Quality

Every new furnace installation follows the same core principles regardless of fuel source: correct sizing, balanced airflow, and safe venting. Chicago’s mechanical code requires licensed technicians to measure total external static pressure, record temperature rise, and confirm blower speed calibration. High efficiency gas furnace installation demands precise vent slopes and condensate drainage to prevent corrosion. Propane and oil systems require leak testing at all joints and verification of regulator pressure. Electric furnaces must have properly sized conductors, circuit breakers, and grounding for high amperage loads. A professional setup prevents ignition issues, carbon monoxide buildup, and premature wear of heat exchangers or heating coils.

Common Furnace Fuel Options and Their Characteristics

- Natural Gas Furnace Installation — Offers the lowest operating cost and highest reliability for Chicago homes. New gas furnace installation often includes direct vent or condensing designs that use PVC venting and achieve over 95 AFUE efficiency.

- Propane Furnace Installation — Ideal for homes without gas lines. Propane systems use sealed burners, outdoor tanks, and dedicated regulators to deliver strong heating performance in off-grid locations.

- Electric Furnace Installation — Clean and simple, with no combustion or exhaust. Requires sufficient electrical capacity and duct airflow calibration to prevent short cycling or cold spots.

- Oil Furnace Installation — Built for heavy-duty heating in older homes. Uses a pump, nozzle, and metal flue, requiring annual service to maintain clean burning and efficiency.

Venting, Combustion, and Condensate Control

Proper venting protects both efficiency and safety. Standard 80% AFUE furnaces use metal B-vent piping with upward draft, while high efficiency models use sealed PVC or CPVC venting that slopes back to the furnace for condensate return. Each vent run must maintain required clearances and slope—typically ¼ inch per foot—to prevent standing water or freezing. Condensate traps, neutralizers, and drains must be installed to keep acidic moisture from damaging drains or concrete. Propane and oil furnaces use metal flues designed for higher temperatures. Electric systems, while vent-free, still require airflow verification to avoid overheating. All installations undergo draft pressure testing and CO monitoring before final startup to ensure safe combustion and correct venting function.

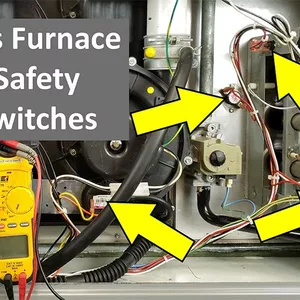

Fuel Delivery, Power Supply, and Safety Controls

Fuel delivery differs by system but always demands precision. Natural gas furnaces connect through approved flexible lines and shutoff valves. Propane installations require outdoor tanks, regulators, and vapor-tight piping. Oil systems use copper or steel lines and a pump to supply the burner under pressure. Electric furnaces depend entirely on dedicated electrical circuits—often 60 to 100 amps—protected by correctly rated breakers. Each system integrates its own safety controls: flame sensors, limit switches, pressure switches, and sequencers. Regular inspection of these components prevents delayed ignition, overheating, or electrical faults. In Chicago, mechanical permits and final inspections confirm compliance before the furnace is placed in service.

Installation Cost and Long-Term Value

Cost differences among fuel types come from materials, labor, and energy infrastructure. Natural gas systems are generally the most affordable to install when gas service is available. Propane and oil systems include added expense for tanks, regulators, and venting hardware. Electric systems may require panel upgrades but avoid venting costs. High efficiency gas furnace installation typically costs more upfront but pays off through reduced utility bills over time. While installation price matters, long-term reliability and efficiency often deliver higher value when the system is properly sized and commissioned. Accurate furnace installation estimate and fuel comparison allow homeowners to make informed investment decisions for comfort and savings.

Key Advantages and Challenges by Fuel Type

- Natural Gas — Reliable, cost-effective, and compatible with high-efficiency systems. Requires venting and condensate management but offers consistent performance and fast heating.

- Propane — Flexible and powerful for remote homes, yet requires regular tank refilling and pressure regulation. Slightly higher fuel cost than natural gas but similar comfort level.

- Electric — Quiet, simple, and clean operation. Works best where electricity rates are moderate and service capacity is adequate. Efficiency is high, but energy costs can vary seasonally.

- Oil — Strong heat output and long equipment lifespan. Needs yearly cleaning, nozzle adjustments, and filter replacement to maintain combustion quality and efficiency.

Maintenance, Service, and Warranty Protection

Ongoing maintenance ensures safe and efficient furnace operation. Gas and propane systems should be inspected annually for burner condition, pressure switches, and vent seals. High efficiency gas furnaces need periodic cleaning of condensate traps and PVC drains. Electric furnaces require coil cleaning and electrical tightening. Oil systems need more frequent maintenance, including nozzle replacement, filter changes, and combustion testing. Properly documented service visits protect manufacturer warranties and validate AFUE performance claims. In Chicago, annual maintenance also supports compliance with code requirements for combustion safety and carbon monoxide prevention.

Choosing the Right Furnace Fuel for Chicago Homes

The ideal furnace fuel type depends on utility access, installation cost, and household priorities. Natural gas remains the leading choice for most urban properties, while propane serves rural locations effectively. Electric furnaces offer clean heat for homes with strong electrical service, and oil systems continue to perform well in legacy installations. Each type, when installed and commissioned by qualified professionals, provides steady warmth and reliability throughout harsh Chicago winters. Careful evaluation of energy costs, equipment design, and installation details ensures that the chosen furnace fuel type delivers both comfort and long-term value.